Check Out QDLM Mixers

CM&C Concrete Machinery & Controls

CM&C Concrete Machinery & Controls IS ON YOUR SIDE!

About QDLM Mixers

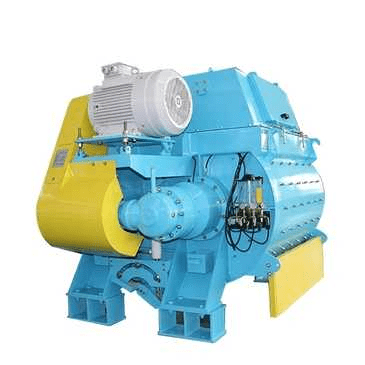

The products produced by our company include twin-shaft mixers, Planetary mixers, dry mortar mixers, PC production lines, etc.

Since its establishment, the company has been "focusing on products and serving attentively" as its mission and taking "efficiency, environmental protection, and energy conservation" as its development philosophy, digging into the difficult problems in the use of equipment and solving problems for customers. Our company has a strong research and development background and has cooperated with many universities successively, focusing on every detail. In the new era, Shaanxi Citron company has a higher and further mission: "master the most core technology, create top domestic equipment." We sincerely invite you to witness it together.

QDLM Mixers

Product Introduction

Product Introduction

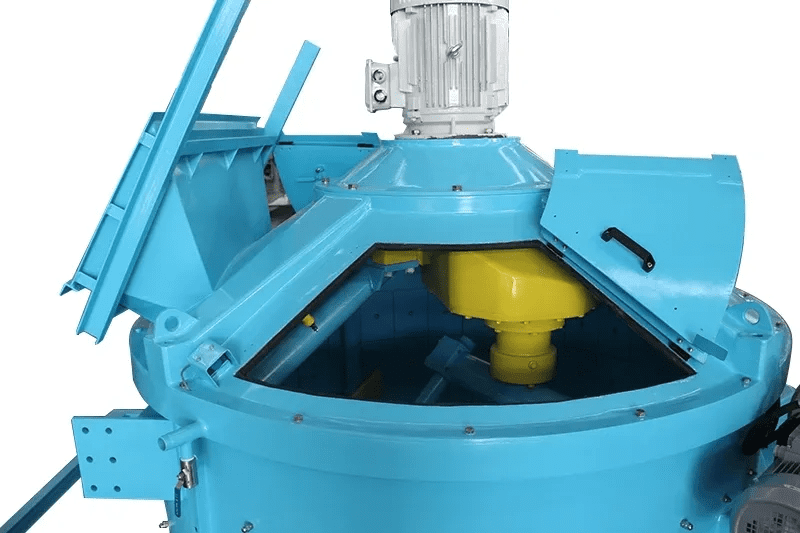

Compact construction. Steady driving. Original mode. Excellent performance. Long operating life. With low investment and operational costs. Easy to install and maintain. No leakage problem. Leading products.

Enterprise qualification/Patent certificates

The first CE certification in the same industry in China.

Planetary Mixer Configuration

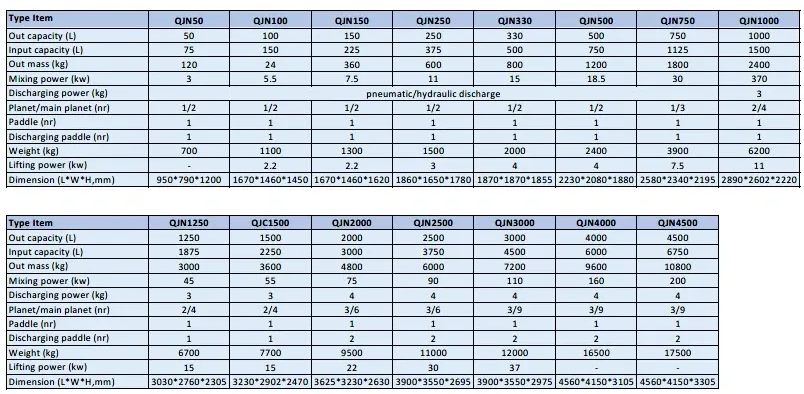

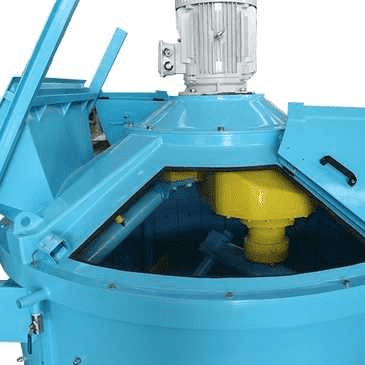

Gearing System

The power transmission is realized by a hard surface gearbox, which our company has specially designed. A fluid clutch is installed between the motor and the gearbox. It can keep the mixer started up normally, even in full-load conditions. The driving force provided by the gearbox drives the mixing arms to do not only a revolution but also a rotation and drives the scraping arms to have a revolution. In this drive mode, the mixing action not only has a rotation but also a revolution. The more complex the motion track, the more turbulent the mixing is, and then the mixer works more effectively, making its mixing more homogeneous.

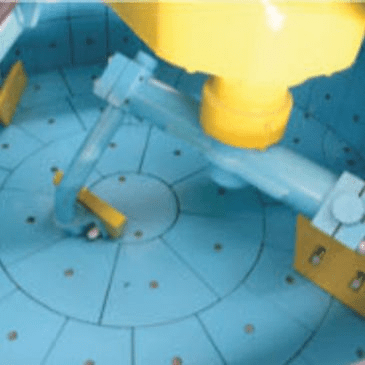

Motion Track

Motion Track

The revolution and rotation speed of the blades have been extensively studied and tested to give the mixer a high output without causing the segregation of materials with different grain sizes and weights. The movement of the material inside the trough is smooth and continuous. As shown in the picture, the blades are configured in such a way that the track covers the whole bottom of the mixer.

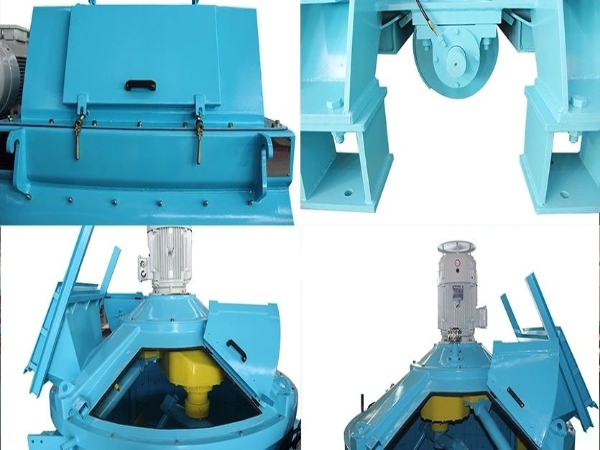

Inspection Port

Inspection Port

There is an observing port on the maintaining door, allowing you to observe the mixing situation without cutting off power.

Mixing & Discharge Devices

Mixing & Discharge Devices

Compulsory mixing is realized by composite moves of extruding and overturning, driven by rotating planets and blades. Mixing blades are designed in a parallelogram structure (patented), which can be turned 180° for reuse to increase service life. A specialized discharge scraper has been designed according to discharge speed in order to increase productivity.

According to the different demands of customers, the discharging door can be opened by hydraulic, pneumatic, or by hand. The number of the discharging door is three at most. There is also a special sealing device on the discharging door to ensure the sealing is reliable.

QDLM

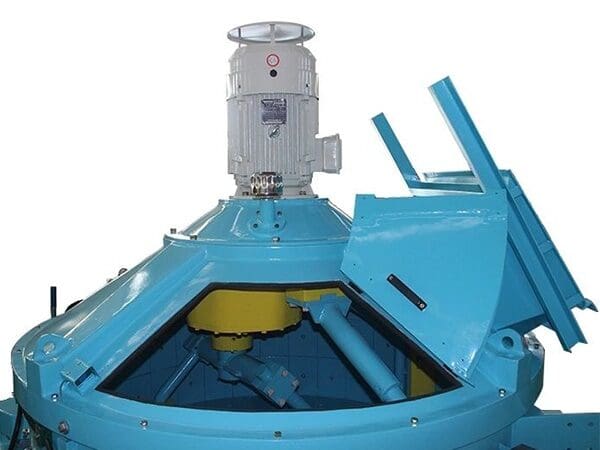

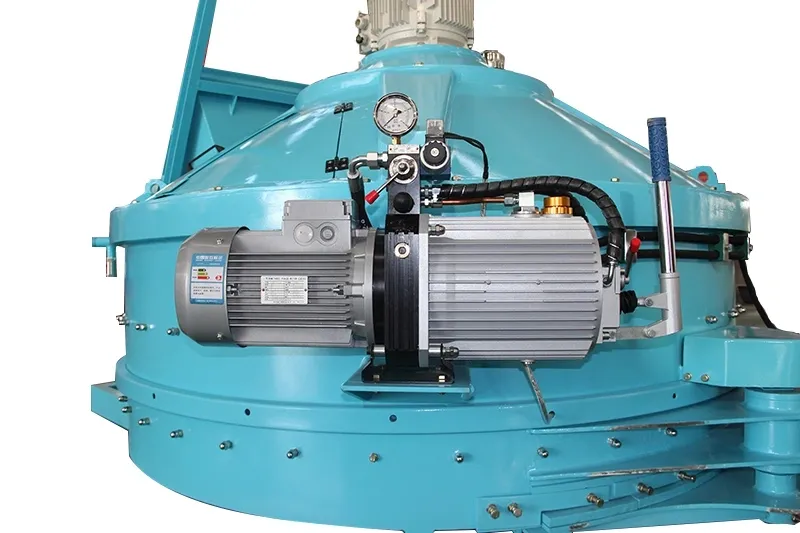

The Hydraulic Power Unit

A specially designed hydraulic power unit is used to provide power for more than one discharging gate. In an emergency, these discharging gates can be opened by hand.

QDLM

Maintaining Door and Security Device

In order to improve the security of using the product, reliable high-sensitive security switches are used in the maintaining door to make the maintaining work-safe and convenient.

QDLM

Water Control

The special designed sprayer is installed on the water pipe. The spraying water cloud can cover more area and also make the mixing more homogeneous.

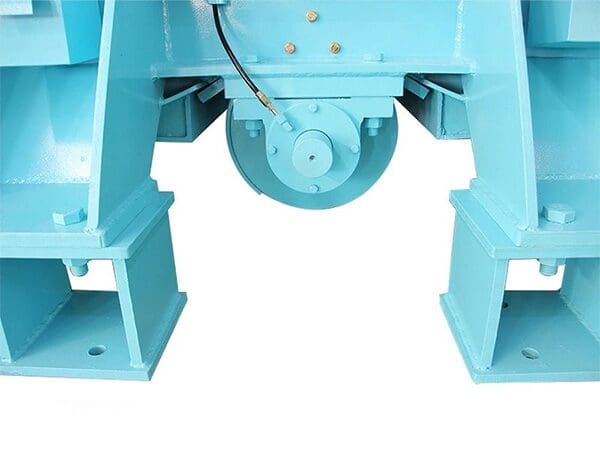

Technical Data